When Chris Sugiuchi, Chase Street’s go to for everything STEM, first heard about the success of the GoFundMe campaign, he quickly reached out to kindred spirits in the community. One such spirit is Robert Beck, a Chase parent and experienced woodworker. He kindly offered to build the Bibliobike. And despite my negligible experience beyond skateboard ramps in middle and high school, Robert also invited me to help.

Robert founded Loki Design in 1996. At his nondescript shop in Comer, Georgia, he juggles residential and commercial furniture, cabinetry and millwork jobs. On one end of the shop, a stack of white custom cabinets with silver hinges almost touches the ceiling. And on the other, a four hundred pound chunk of vintage piano guts, destined to become a table, rests on a cart – a relic that would pique the curiosity of any avid maker.

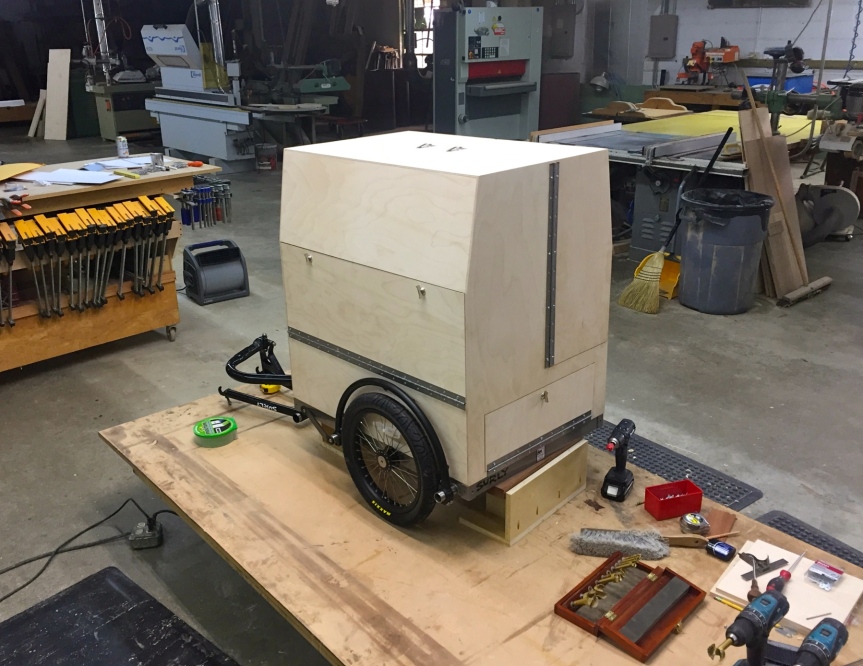

Our process began with a discussion of modifications to the original design, some aesthetic and others utilitarian. For example, Robert chose Baltic birch wood because it’s stronger and lighter. He also upgraded the metal parts to stainless steel, which will last longer when exposed to the elements. Other tweaks happened organically while moving through the different stages.

I had no idea summer would begin with an apprenticeship. At each step, Robert modeled the technique(s), then set me loose. Naturally, I was nervous at times. I think he could sense it because he simply responded, “You’ll find your way.”

In addition to patiently answering tons of rookie questions and using jokes to ease the stress when I made mistakes, Robert calculated measurements and cut the pieces. He taught me how to use a router to cut rabbets (not a typo) and dadoes, which are essentially slots.

Robert also taught me how to smooth the wood to prevent future splinters with the most sophisticated sander I’ll probably ever use. The incredibly ergonomic blobject features a built-in vacuum and Bluetooth compatibility. If stolen, he could turn it off remotely with his phone (though it’s doubtful Robert has enabled the feature). The sander and I have spent quite a bit of time together, and Robert and I have now surpassed thirty hours of work. Here’s an overly simplified breakdown of our process so far:

- Discuss modifications.

- Cut pieces.

- Sand pieces.

- Rout rabbets and dadoes.

- Dry fit parts together.

- Glue them.

- Excessively clamp pieces together.

- Remove clamps.

- Attach latches and hinges.

- Remove them.

- Take apart three main parts/shelves.

- Sand corners, edges and smudges.

- Stain everything.

During math each year, we discuss the importance of attending to precision. I wish I could bring my students to Robert’s shop to model what that looks like in action beyond the abstract.

So we’re nearing the end of construction, and in Robert’s words, “We’ll get there.”

Very nice book cart, great project to apprentice on and to have such a cool shop and nice tools to work with! Kudos to you Cam

LikeLike

Thanks again!

LikeLike